Hydraulic Flap Barricade Machine Quality Assurance Durable Complete Specifications

2022-11-08

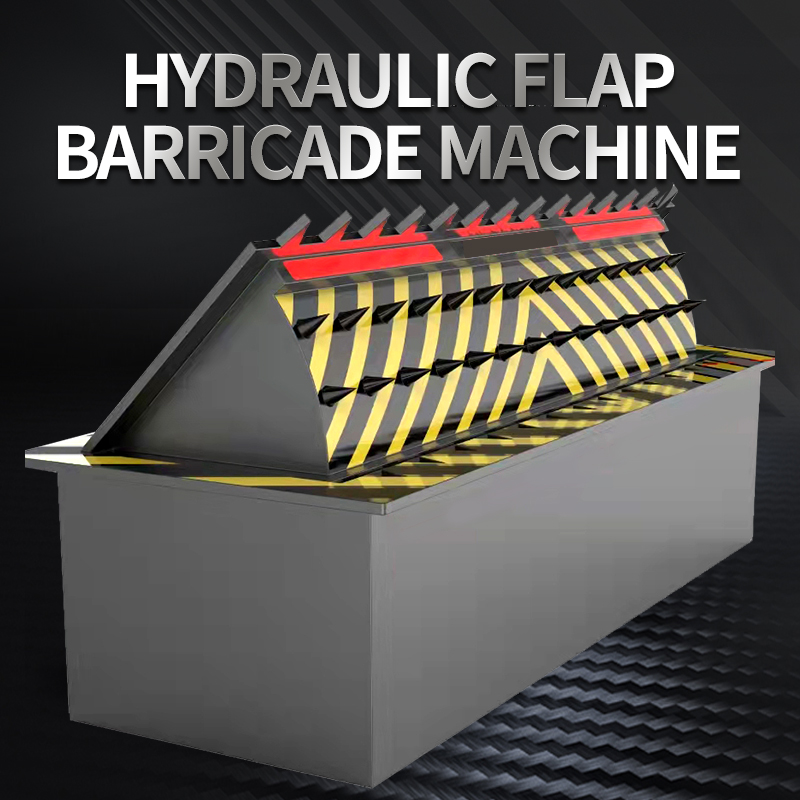

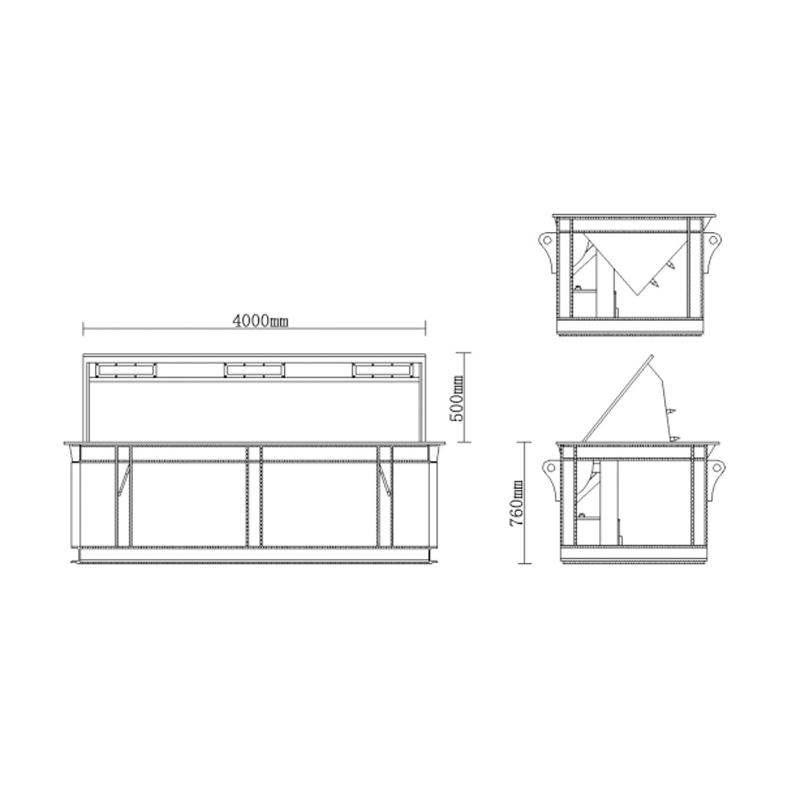

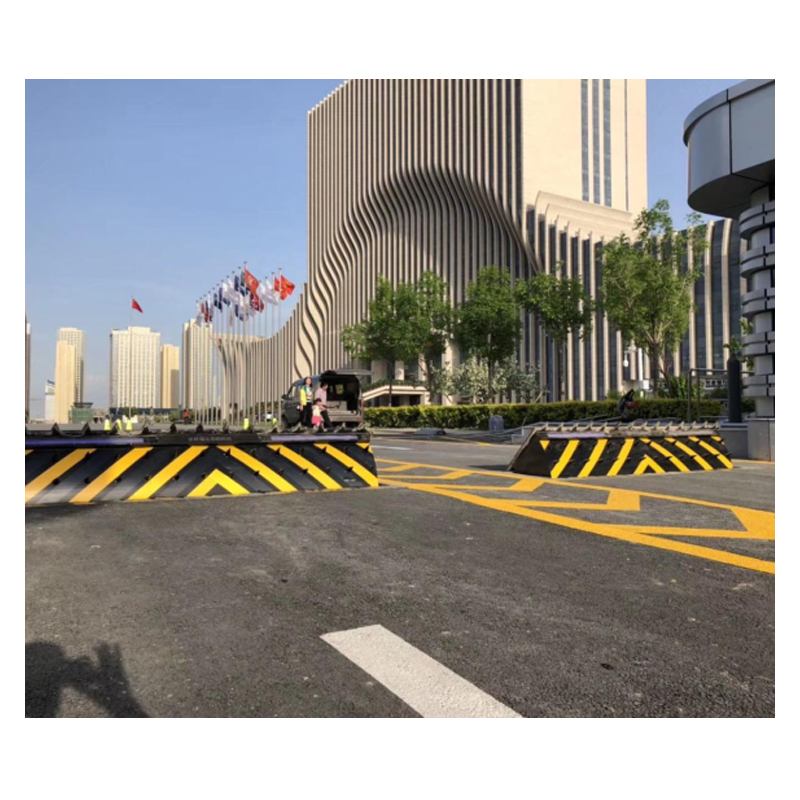

Hydraulic flap roadblock machine, also referred to as roadblock machine, is mainly divided into roadblock machine with hairtip and roadblock machine without hairtip; The hydraulic flap barricade belongs to the equipment for controlling the passage of road vehicles, which can be used together with the road gate control system or used alone. It is specially designed and developed to prevent unauthorized vehicles from intruding into sensitive areas, with high practicability, reliability and security; It is composed of three parts: main frame, hydraulic transmission station and electric control. According to the different needs of different customers, it has a variety of configuration methods for users to choose, which can meet the functional requirements of various customers. Then the following section will explain the application scenario of the hydraulic flap roadblock machine and the precautions for use and maintenance.

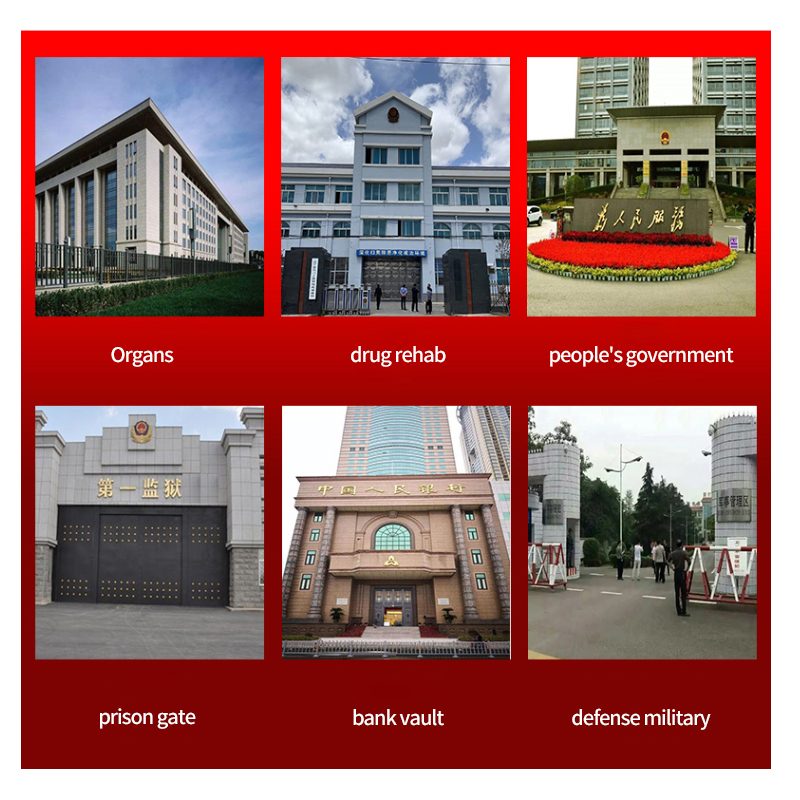

The hydraulic flap roadblock machine is widely used to provide security for key prevention departments such as troops, prisons, road checkpoints, warehouses, wharves, etc., to prevent unauthorized vehicles from breaking into it. It has high practicability, reliability and safety. In some places where vehicles need to be restricted, its purpose is to effectively control the access of vehicles. Click to learn about the automatic lifting column.

Precautions for use and maintenance of turnover barrier machine:

1. When there are vehicles or pedestrians above the anti-collision roll over barrier, it shall be strictly lifted to avoid hazards.

2. Keep the bottom of the anti-collision board barrier unblocked and the surrounding clean to ensure the service life, performance and waterproof sealing of the lifting barrier machine parts.

3. During the operation of anti-collision and anti-terrorism roadblock, continuous ascent and descent shall be prevented. Lifting and lowering should not be switched continuously and rapidly, which is easy to shorten the service life of motor and hydraulic pump.

4. In large snow and ice days, if there is serious ice inside the pile of the bump proof board roadblock, the lifting and lowering shall be stopped, and heating and other methods can be used after freezing.

5. Regularly check the oil level in the oil tank of the bump proof barrier. If the oil level is lower than the bottom line, add oil; If the oil page becomes dark and turbid, you need to think about changing the oil page.

1. The structure is firm and durable, with large load, stable action and low noise.

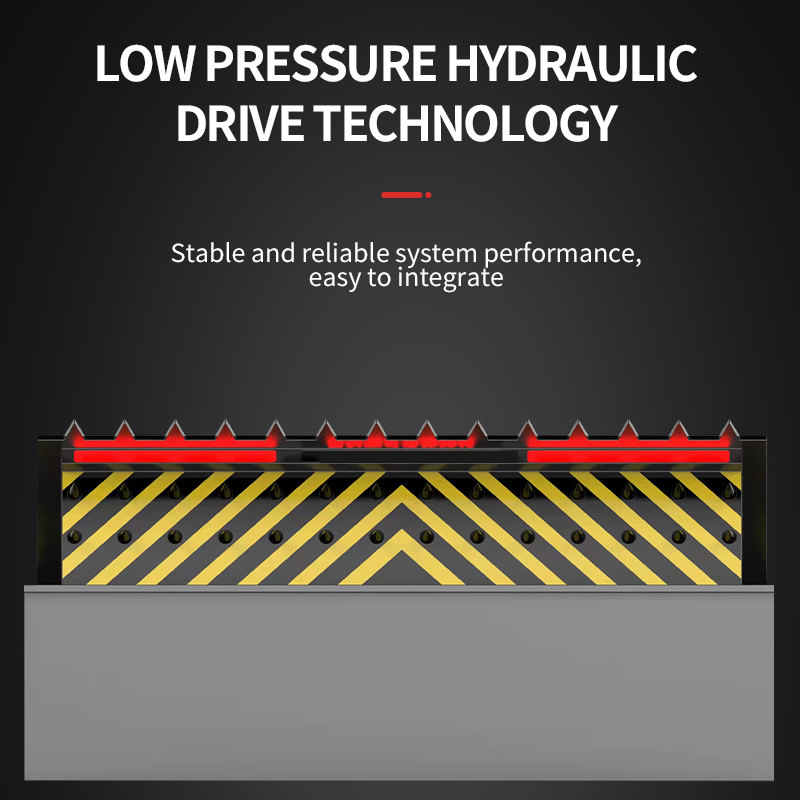

2. With PLC control, the system has stable and reliable operation performance and is convenient for integration.

3. The roadblock machine can be linked with other equipment such as the road gate, and can also be combined with other control equipment to achieve automatic control.

4. In case of power failure or failure, such as when the roadblock machine is in the raised state and needs to be lowered, the raised roadblock machine cover can be manually lowered to the horizontal position to allow vehicles to pass.

5. The international leading low pressure hydraulic drive technology is adopted, and the whole system is safe, reliable and stable.

6. The remote control device, by means of wireless remote control, can control the lifting and lowering of roadblocks within about 30 meters around the controller (depending on the on-site radio communication environment).

7. The following functions can be added according to user requirements:

① Card swiping control: add card swiping device, which can automatically control the lifting and lowering of roadblocks through card swiping.

②Linkage between road gates and roadblocks: with additional road gates (car stops)/access control, the linkage between road gates, access control and roadblocks can be realized.

③Connection with computer management system or charging system: it can be connected with management system and charging system and controlled by computer.

Chengdu Titan Technology Co., Ltd. specializes in the research and development, production and sales of lifting barricade products, and covers the system integration, design and installation of intelligent vehicle management, security and parking lot facilities engineering. The factory covers an area of more than 30,000 square meters, has a complete set of CNC finishing equipment, and has a complete range of products. At the same time, it continues to introduce high-quality products and solutions in this field, which greatly meets the needs of the military, public security, prisons, government agencies, embassies, transportation, finance , telecommunications, hotels and other industries application needs.

Adhering to the business tenet of "integrity, service, efficiency and innovation", the company has a high-level R&D team and management team, and has gathered a large number of professional technicians and construction personnel in the industry. The product quality has always been in the leading position in the domestic industry.

The company adheres to the service tenet of "tough people, ingenious ingenuity", and provides users with "excellent service and excellent quality" with "excellent technology and excellent management". Always adhere to the interests of users in the heart, "urgent users, think about what users think", and sincerely cooperate with friends from all walks of life to create a brilliant career!

Huang Jing

28810286@qq.com